After validation of performance of a first prototype machined in aluminium for SV GRAIN DE SAIL 2, we designed a second iteration of propeller according to bronze properties.

Since it has much more strength than aluminium, bronze alloy allows thinner blade sections and an increase in performances. It helps to reduce tip cavitation as well.

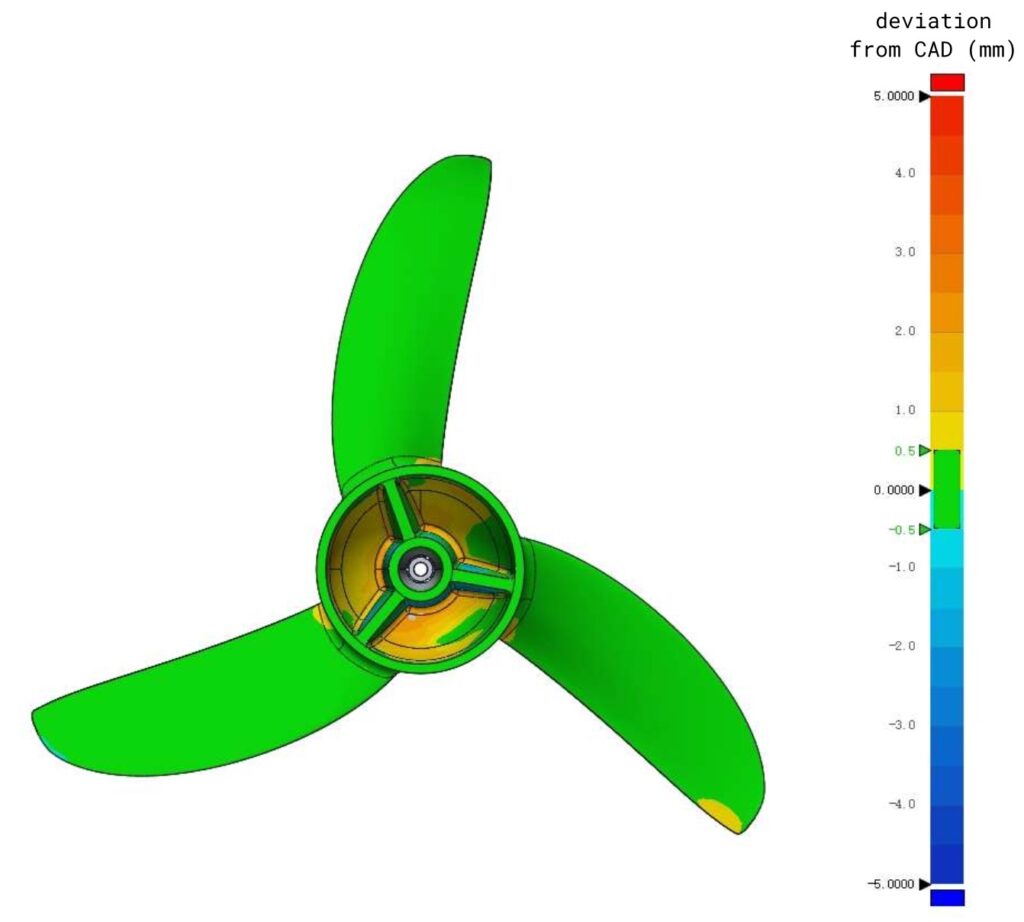

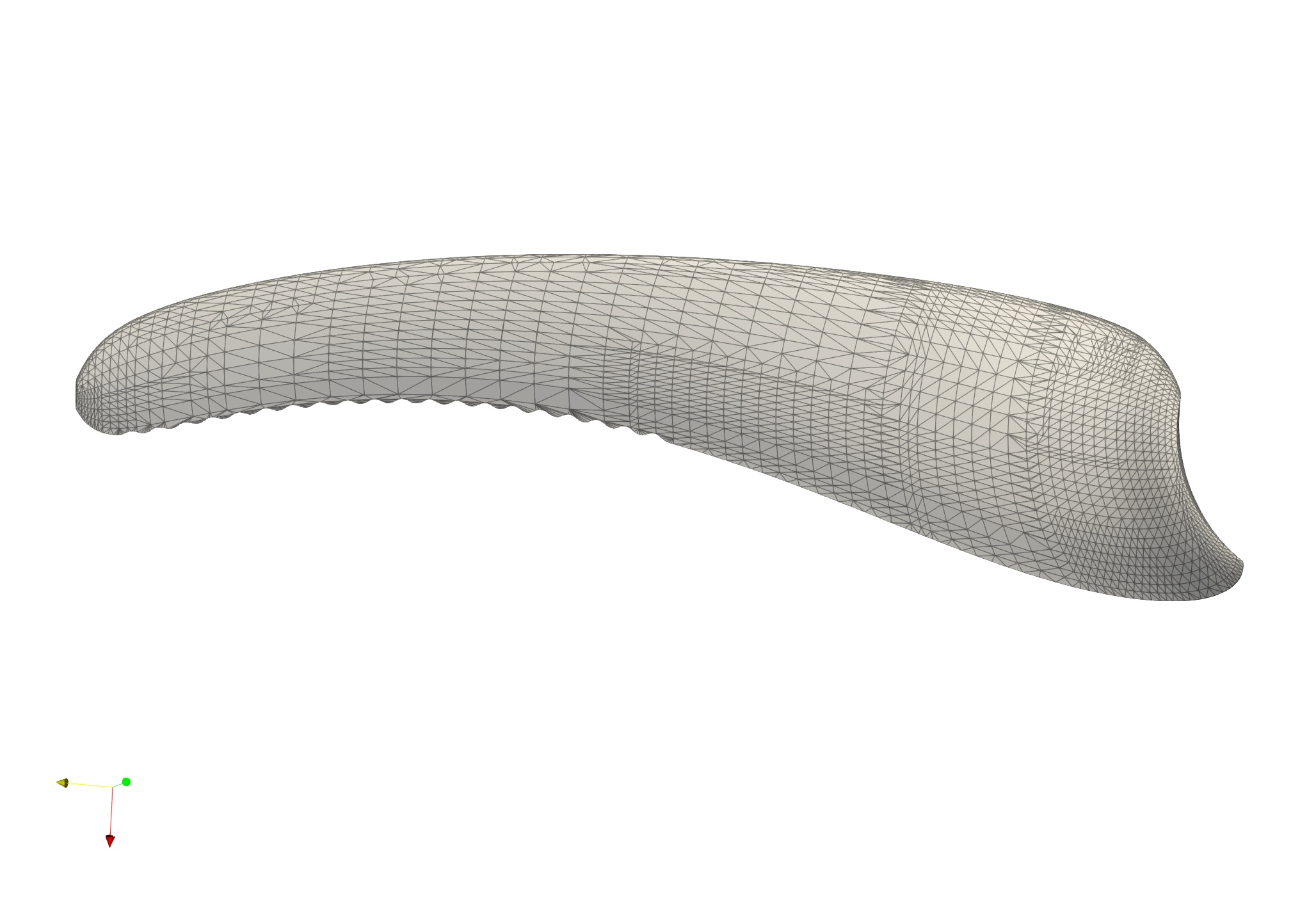

The fabrication quality was checked with 3D laser scanning method to ensure the final shape is close to the ideal one. The measured deviation on this part is typically +/- 0.3 mm but some small areas show a bit less accuracy.